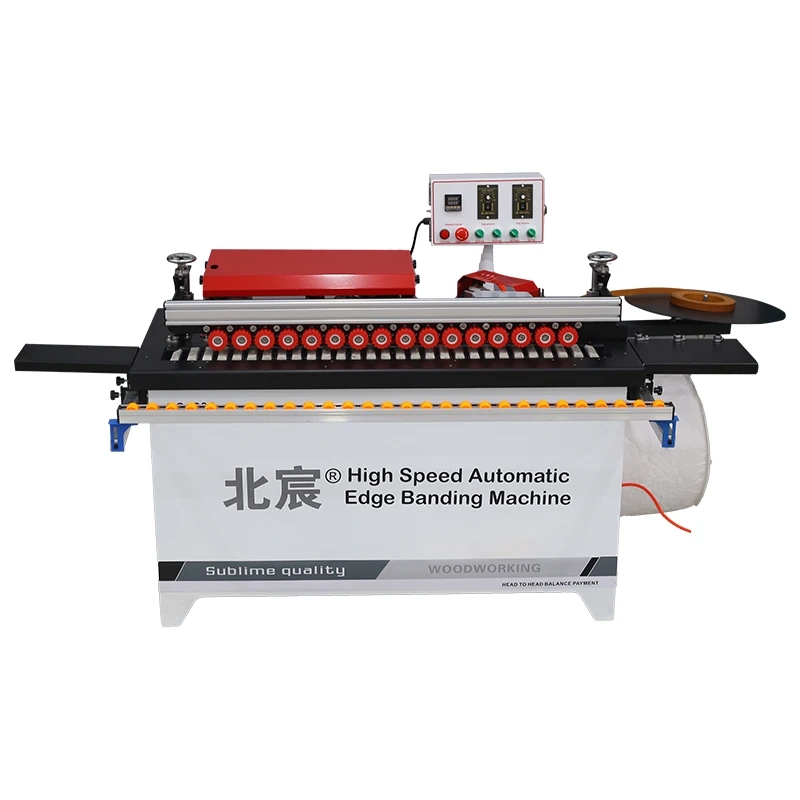

Automatic Edge Banding Machine equipment, Manual Edge Banding Machine, Wood Edge Banding Machine, PVC Edge Banding Machine, Edgebander for Sale

The edge banding machine is utilized for applying edge bands to both straight and curved panel edges in custom furniture manufacturing. Woodworking edge banding machines are categorized into manual and automatic types. These machines are specifically engineered to provide businesses with efficient, accurate, and reliable edge banding services and solutions tailored for wood processing needs.

Edge Banding Machine for Sale

Home » Edge Banding Mahicne

-

Curve Edge Banding Machine

ST-30 For Furniture Bander multifunction portable handheld Edge Banding

$190.00 加入购物车 -

Automatic Edge Banding Machine

ST-70 upgraded roller mini portable edge bander machine curve woodworking Multifunction mini manual edging machine

$253.00 加入购物车 -

Automatic Edge Banding Machine

Edging machine ST-50 pvc edge band mdf board wood based panels machinery small mini portable edge banding machine

$210.00 加入购物车 -

Automatic Edge Banding Machine

Beichen FX-10 Edge Banding Multifunctional Sealing And Repairing Wood Based Panels Machinery Thread Trimming Machine

$340.00 加入购物车 -

Automatic Edge Banding Machine

FX-20 Edgebander Automatic Mini Homeuse Wood Pvc 3mm Edge Banding Machine

$350.00 加入购物车 -

Automatic Edge Banding Machine

DW802 Woodworking adhesive edge banding machine automatic PVC edge bander MDF panel furniture wood edge banding machine price

$798.00 加入购物车 -

Bevel Straight Edge Banding Machine

Beichen XZF450 High Speed Automatic Oblique Straight Edge Banding Machine Best Quality for Woodworking for Wood Industry

$3,000.00 加入购物车

Related Articles

Popular Mini FX-20 Small Woodworking Edge Banding Machine

The Beichen FX-20 Sm

ST-30 Furniture Portable PVC Melamine Edge Banding Machine

Beichen ST-30 Furnit

ST-70 Upgraded Roller Mini Portable Edge Banding Machine

The Beichen updated

Soft Forming Edge Banding Machine DW985 for Highly Efficient Woodworking

Beichen’s Soft Formi

DW3600 Edge Banding Machine for High-Accuracy Wood Panel Finishing

Beichen DW3600 edge

Buyer Guide

Edge banding machine is the focal point in contemporary furniture manufacturing. With respect to conventional edge banding processes performed manually, the edge banding machine produces edges with sharper, more finely finished, and smoother cuts that greatly improve the looks and quality of furniture.

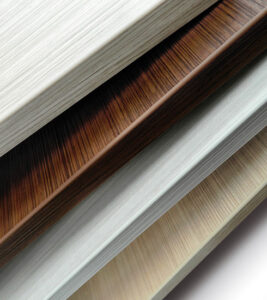

As we all know, cabinet edge banding is an important process of furniture production. Apart from improving the appearance of cabinets and smoother in touch, there is high-quality edge banding that also allows for effective control of formaldehyde emission from panels, hence another environmental protection for living space indoors. Thus, edge banding machine is a necessary equipment for the whole panel furniture production line.

The edge banding machine basically comprises the main frame, several processing units, and control system. The processing units are pre-milling unit, edge tape conveying unit, edge banding unit, cutting unit, trimming unit, rounding unit, scraping unit, and polishing unit. All these units play a certain function to ensure the efficiency and accuracy of the edge banding process.

With its high degree of automation, good stability performance, reliability, and durability and its reasonable price, the Beichen edge banding machine is especially suitable for furniture production factories, large and small, cabinet manufacturers, and other panel furniture producers. With Beichen you can experience better edge banding quality and also cater to a cleaner production process.

Edge banding machines can be divided based on the level of automation, primarily consisting of manual edge banders, half-automatic edging machines, and automatic edge banding machines. All the types have special features and creates special banding effects based on different production requirements.

The most significant distinction between fully automatic and semi-automatic edge banders is their processing capacity. Semi-automatic machines are capable of executing simple operations like gluing, edge banding, trimming upper and lower parts, and polishing. Fully automatic edging machines, however, are equipped with advanced technology such as pre-milling, gluing, edge banding, trimming, contour tracing, scraping, and polishing. Owing to their high cost-performance ratio, fully automatic edge banders have replaced semi-automatic models from production units in the long term.

From the edge banding shape point of view, edging machines are classified into straight edge banders, straight and curved edge banders, and bevel edge banders. They are all designed to work with particular edge profiles, providing precision and flexibility in furniture manufacturing.

Beichen edge banding machines reign supreme in the industry with its world-class automation, reliability, and efficiency. If you require semi-automatic or full automatic machinery, Beichen provides state-of-the-art technology for your production requirements. With Beichen, you can experience the convenience of producing perfect edge banding finishes and maximize your process to increase your productivity. Opt for Beichen for a superior, more efficient edge banding solution.

In the current market, five fundamental operations are offered in the majority of automatic edge banding industrial machines: banding and gluing, trimming, end cutting, scraping, and polishing. These fundamental operations guarantee quality edge banding on different panels and are therefore inevitable in contemporary furniture manufacturing.

Basic Functions

Gluing and Banding: Six impression wheels (1 big and 5 small) strongly press the edge banding tape after hot melt glue application is complete. The gate on the cylinder-controlled glue pot provides even application of glue with consistent thickness and eliminates slippage of tape along with improving bond security.

End Cutting: This operation takes off excess edge banding tape from each end of the board with high-speed motor-driven saw blades. Standard and high-speed double guide rail types of end cutting are available in edge banders with a cylinder system for pressure holding precise cuts.

Trimming: Trimming is used to cut off excess material from above and below the edge band using trimming knives. The process includes rough and fine trimming, the second of which produces a neater and smoother finish. Less costly equipment might have only rough trimming, producing less delicate results.

Scraping: Scraping removes corrugated marks that are caused by curved edge banding, leaving a silky finish. Flexible scraping is very well-liked because it performs better without harming the edge band or board.

Polishing: Polishing uses a cotton polishing wheel to eliminate burrs and excess glue lines, leaving a polished and clean edge.

Advanced Features:

Pre-milling: This feature smooths out rough surfaces or cutting saw imperfections, allowing the edge banding tape to seat securely for a perfect finish.

Profiling Tracking: Or otherwise referred to as corner rounding, this feature rounds off sharp corners to attain a safe and better-looking finish. Advanced designs provide precision and stability.

Cleaning: This feature cleans off excess glue from the glue pot so that the machine is in optimal form and condition.

Slotting: Slots wardrobe side panels, bottom plates, or aluminium edges directly, cutting down on extra sawing operations.

Pneumatic Cutter Adjustment: Enables quick adjustment of edge band thickness from the screen, and it facilitates easy changing between various kinds of panels and thicknesses.

Upper Glue Pot: Though the majority of edge banders incorporate a lower glue pot, an upper glue pot is needed for using PUR glue, providing more adhesive flexibility.

Double Glue Pots: Allows simultaneous use of two types of glue, saving time and effort spent on switching the color or kind of glue.

Beichen edge banding machines are renowned for their new functions, accuracy, and reliability. With Beichen, you can enjoy premium edge banding outcomes and maximize your production efficiency. Regardless of whether you require fundamental functions or advanced functions, Beichen provides innovative solutions that meet your demands. Select Beichen for a seamless and professional edge banding process.

The wood edge banding machine is specifically applied to edge banding of medium-density fiberboard, wood board, solid wood board, particleboard, etc. That is why we also refer to the machine as plywood edging, MDF edging, etc. Depending on wood material, it can finish birch edge banding, maple edge banding, walnut edge banding, and other wood veneer edge banding.

The completely automatic edge banding machine is widely applied in middle and large-sized furniture factories. It has such great advantages as stable operation, high automation degree, stable performance, and low cost. In addition, the automatic edge bander machine is an indispensable CNC machine in most of the furniture production lines.

The manual edge banding machine is ideal for straight and irregular banding edges. The manual edge bander machine is the most suitable edge banding machine appropriate for small shop sizes. Additionally, it can be conveniently shifted from one office location to another to execute the banding process at the workstation.