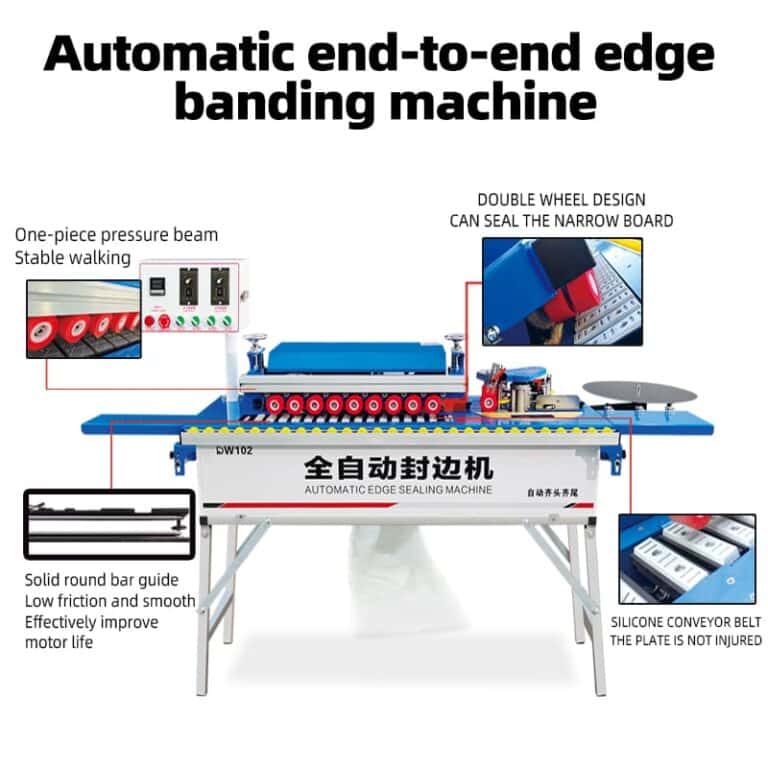

DW102 Automatic MDF Edge Bander: Revolutionizing Woodworking with Efficiency and Precision

- Home

- Blog Details

DW102 Automatic MDF Edge Bander In woodworking, Efficiency and precision are the main acts. The DW102 Automatic MDF Edge Banding Machine is an innovation that simplifies the edge banding function for all wood industries. It offers ease of use, multipurpose and robust construction in an attempt to provide better edge banding quality.

Key Point and Benefits

Effortless Operation: The DW102 is made to work effortlessly, Reduce physical labor and maximize the level of productivity. Its user-friendly interface ensure stable and optimal working environment.

Versatile Application: Applicable in a variety of situations and industries, including building material stores, construction sites, farms, household use, hotels, machinery repair stores, factory plants, and other wood working processes.

High-Quality Edge Banding: The vacuum capacity of DW102 is 1200W, and its edge banding process is secured and durable. 1000ml glue pot size and air source pressure 0.5-0.8MPa guarantee the ideal bonding conditions among various materials.

Customizable Edge Banding: The machine offers adjustable edge banding thickness (0.3-3mm) and height (0-50mm) to meet various users and diverse material demands.

Durable Construction: Constructed from heavy-duty components, such as bearings, gears, gearboxes, motors, and a PLC system, all of which are covered for 1 year.

Technical Specifications

Model: DW102

Power: 3.8kW

Voltage: 220V/110V

Weight: 75 kg

Dimensions: 128*47*69CM

Edge Banding Thickness: 0.3-3mm

Edge Banding Height: 0-50mm

Glue Pot Capacity: 1000ml

Air Source Pressure: 0.5-0.8Mpa

Vacuum Power: 1200W

Minimum Sheet Length: 25cm

Minimum Sheet Width: 5cm

Edge Banding Technology

The DW102 utilizes the best-in-class edge banding technology to deliver precision and consistent results. Edge banding is the process of edge covering raw edges of material such as MDF, particleboard, or plywood to produce a finished appearance and seal the core material. It is done with heat, pressure, and adhesive. Straight line edge banding machines such as the DW102 are used for the application of edge banding on straight or slightly curved panels, In the woodworking furniture sector is invaluable to the primary products.

The Edgebanding Process

DW102 simplifies the process with these functions:

Gluing: Sprays hot melt glue onto the panel edge.

Edge Feeding: Automatically feeds the edge banding material.

Pressing: Presses the edge banding material onto the panel edge.

End Trimming: Trims the edge banding material to the proper length at the front and back of the panel.

Fine Trimming: Closely trims the top and bottom of the banding material.

Cleaning: Having a unit to eliminate excess residual glue.

Conclusion

The DW102 Automatic MDF Edge Bander is a convenient machine for wood companies seeking to boost their edge banding capacity. From its simple operation, utility application, and rugged build, the DW102 provides consistent, high-quality outputs, which makes it a sound investment for companies of any size.

For more to read, pricing, and custom orders, check out the Official DW102 Product Page on Alibaba.