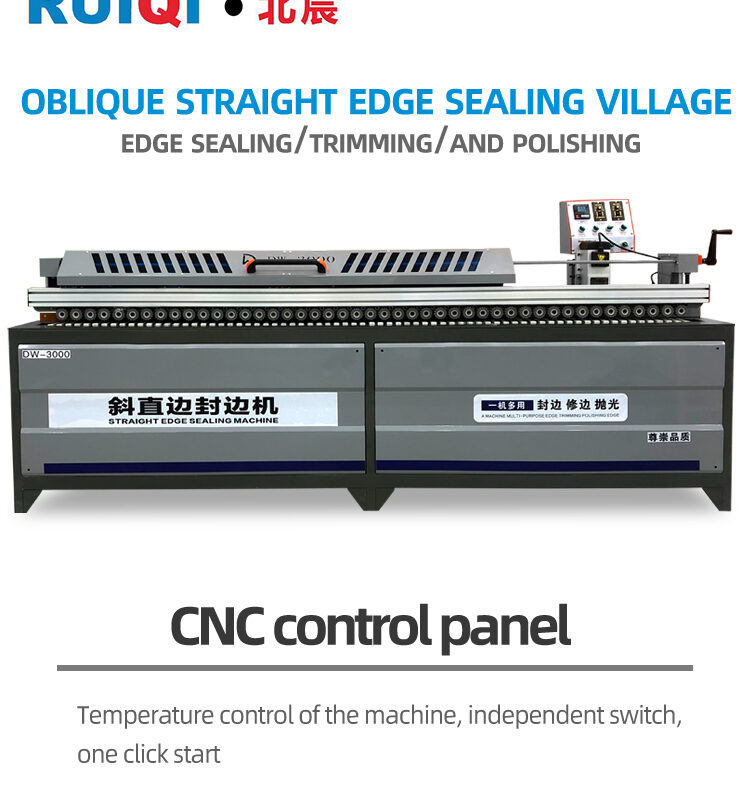

DW3000 Fully Automatic 45 Degree Oblique Straight Edge Banding Machine

- Home

- Blog Details

Beichen DW3000 Oblique Straight edge banding machine is an automatic one which is capable of performing oblique as well as straight-line edge banding with perfect accuracy. The best-suited machine for panel furniture production and cabinetry production, DW3000 gets its place in workshops and mass-production units. With first-rate functionality and high-speed machining, DW3000 provides finishes with a colossus increase in productivity.

Key DW3000 Edge Banding Machine Features

Smooth Automatic Operation

DW3000 operates automatically with less manual handling. This allows manufacturers to focus on scale-up of production while offering smooth, precise edge finishes to furniture panels.

45-degree Oblique and Straight-Line Capabilities

Since it is designed to process 45-degree oblique and straight-line edge banding, DW3000 is also in a position to handle multiple design specifications. Its versatility positions it to readily accommodate furniture makers who are creating new, customized designs.

High-Speed Panel Processing

The DW3000 has a panel feed speed of 12m/min, which is suitable for mass production lines. The rate offers high-volume processing of hundreds of panels by bulk quantities at the expense of edge quality.

Multi-Functional Design

The DW3000 comes with a variety of high-end edge banding functions, including:

Pre-Milling: Is used to prepare the edges for a high-strength, high-precision bond.

Gluing: Offers consistent adhesive application for a smooth surface.

Trimming: Offers coarse and fine trimming for uniform edge quality.

End Trimming and Corner Trimming: Processes angled or straight corners efficiently.

Scraping and Buffing: The edges are buffed to a professional, uniform finish.

Selective Voltage Options

The equipment is designed with the capability of offering various voltage configurations, such as 380V, 415V, or customized, in order to be compatible with diversified production scenarios.

Solid and Durable Construction

Having been designed with tough core components such as high-grade bearings, motors, and PLC systems, DW3000 is highly durable. Furthermore, it is supported by a 1-year guarantee that suits mass-scale production procedures.

Technical Specifications

Total Power: 11KW

Edge Banding Thickness Range: 0.3mm–3mm

Edge Banding Height: 0–50mm

Minimum Panel Size: 30cm x 15cm

Glue Pot Capacity: 4000ml

DW3000 has the capability of handling different types of panels and finishes, hence it is a perfection machine for future woodworking.

Space-Saving but Industrial-Level Performance

Measuring 312(L) x 74(W) x 115(H) cm, gross weight of 430 kg, the DW3000 is space-saving but gives industrial-level performance. With an extremely complex designed frame, DW3000 makes it strong, efficient, and easy to maintain.

Applications of the DW3000

DW3000 is utilized for:

Custom Furniture Production: Best for curved edges and detailed designs.

Manufacture of Cabinets: Provides accurate finishing for kitchen cabinets and wardrobes.

Plywood Production: Handles high-speed panel finishing for bulk manufacturing settings.

Why Choose Beichen’s DW3000 Edge Banding Machine?

Beichen DW3000 Oblique Straight edge banding machine is designed to be efficient and all-purpose with large production capacity in each step but guaranteeing precise accuracy in each procedure. Best solution for industry professionals to bring efficiency, stability, and immaculate edge quality to their cabinet or furniture productions.